The Pallet Shuttle: A Cutting-edge Technology for Efficient Warehouse Operations

With the rapid advancement of technology, the logistics industry has witnessed significant transformations in recent years. One such innovation is the pallet shuttle system, which revolutionizes warehouse operations by enhancing efficiency and productivity. In this article, we will explore the features and benefits of the pallet shuttle system, with a focus on its application in Ivory Coast.

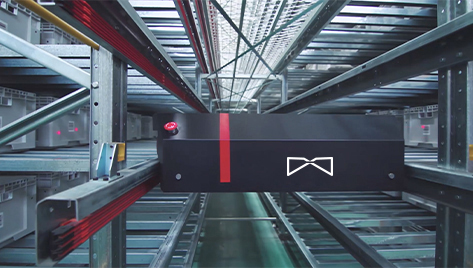

HWArobotics: The Pioneer behind Pallet Shuttle System

HWArobotics is at the forefront of developing cutting-edge solutions for warehouse automation. Their flagship product, the FPSS1500A four-directional pallet shuttle system, stands out as an exceptional example of their expertise. This state-of-the-art technology is entirely composed of European components and operates solely on electricity.

One key advantage offered by HWArobotics‘ pallet shuttle system is its superior quality and reliability. By utilizing top-notch European branded components, it ensures optimal performance while minimizing failure rates. Additionally, this innovative solution incorporates AI scheduling algorithms to achieve swarm intelligence within its PSR (Pallet Shuttle Rack) system.

Promoting Efficiency with Advanced Features

The pallet shuttle system offers several remarkable features that contribute to enhanced efficiency in warehouse operations:

- All-electric Drive: Unlike traditional systems that rely on manual labor or fuel-powered machinery, HWArobotics’ pallet shuttle adopts an all-electric drive mechanism. This not only reduces carbon emissions but also provides precise control over movements within the warehouse.

- Rapid Delivery: With a commitment to customer satisfaction, HWArobotics guarantees speedy delivery within 100 days after contract price payment completion. This prompt service enables businesses to quickly integrate this advanced technology into their operations.

- Unparalleled Reliability: The pallet shuttle system adheres to the highest reliability standards, ensuring uninterrupted performance even in demanding warehouse environments. This reliability translates into increased productivity and minimized downtime.

- AI Deployment: Leveraging artificial intelligence, the pallet shuttle system optimizes efficiency by automatically adjusting its operations based on factors such as the number of vehicles and rack structure. This intelligent scheduling algorithm maximizes throughput while minimizing unnecessary movements.

The Pallet Shuttle System: Transforming Warehouse Operations in Ivory Coast

Ivory Coast, a rapidly developing country in West Africa, has witnessed significant growth in its logistics sector. With an increasing demand for efficient warehousing solutions, the introduction of HWArobotics’ pallet shuttle system holds immense potential for transforming warehouse operations in Ivory Coast.

The implementation of this cutting-edge technology can revolutionize case picking processes by streamlining inventory management and optimizing storage space utilization. By automating material handling tasks with precision and speed, businesses operating in Ivory Coast can achieve higher levels of operational efficiency and cost-effectiveness.

In Conclusion

The pallet shuttle system developed by HWArobotics represents a remarkable advancement in warehouse automation technology. Its integration of European components, all-electric drive mechanism, AI deployment capabilities, and unmatched reliability make it an ideal solution for enhancing efficiency within warehouses. As countries like Ivory Coast embrace these innovative technologies, they pave the way for improved logistics infrastructure that will support economic growth and development.