From Design to Finished Product: The Benefits of CNC Turning Manufacturing

What is CNC Turning Manufacturing?

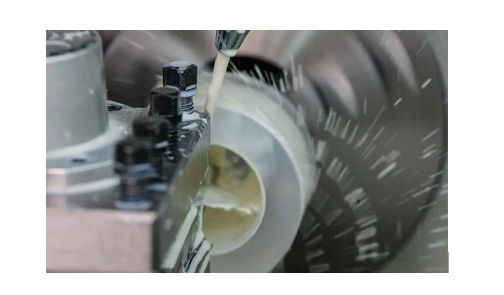

Huapin CNC turning manufacturing is a process where computer-controlled lathes or mills are used to create parts from raw materials. This process can be used to create both small and large parts with a high degree of accuracy. CNC turning is a versatile manufacturing process that can be used to create a wide variety of parts, including those with complex geometries.

Benefits of CNC Turning Manufacturing

Huapin CNC turning is a popular manufacturing process for creating cylindrical parts. The process is often used to create parts for the medical and aerospace industries because it can create highly accurate and repeatable parts. CNC turning offers a number of advantages over traditional machining methods:

Increased accuracy: CNC machines can hold very tight tolerances, making them ideal for critical applications.

Repeatability: CNC machines can produce identical parts time after time, ensuring consistent quality.

Increased productivity: CNC machines can work faster than manual machines, allowing more parts to be produced in a shorter timeframe.

Flexibility: CNC machines can be quickly programmed to produce different part designs, making them ideal for prototyping or small batch production runs.

Conclusion

CNC turning manufacturing is a reliable and efficient process that can produce finely crafted products of any shape or size in an incredibly short amount of time. The high level of accuracy and repeatability means that there’s no need for manual labor, which results in lower costs and quicker turnaround times. Whether you’re looking for custom parts for your home projects or mass-produced components for commercial use, CNC turning manufacturing is the best way to get from design to finished product with ease.